Room 503, Building 2, Xinghu Bay, Ningbo City

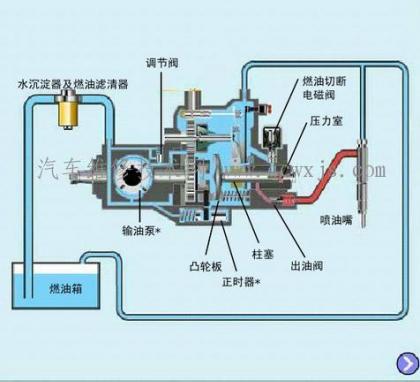

Working principle of diesel engine fuel injection pump

The fuel injection pump is the most important component in the diesel supply system, and its performance and quality have a great impact on the diesel engine, known as the "heart" of the diesel engine

There are three main types of fuel injection pumps: inline, distributed, and single unit. Regardless of which type, the key to a fuel injection pump lies in the word "pump". The quantity, pressure, and timing of the pump oil must be very precise and automatically adjusted according to the load. The fuel injection pump is a finely processed and complex manufacturing component. Currently, the fuel injection pumps for general automotive diesel engines both domestically and internationally are produced by a few professional factories around the world

Each plunger system of an inline fuel injection pump corresponds to one cylinder, and there are four plunger systems for every four cylinders. Therefore, it has a relatively large volume and is mostly used in medium-sized and above vehicles. For example, diesel engines on buses and large trucks generally use inline fuel injection pumps

* The key component of a fuel injection pump is the plunger. If we compare it to a common syringe in hospitals, the movable plunger is called the plunger, and the syringe is called the plunger sleeve. Assuming a spring is installed inside the syringe to support one end of the plunger, and the other end of the plunger contacts the camshaft, when the camshaft rotates once, the plunger will move up and down inside the plunger sleeve. This is the basic movement mode of the fuel injection pump plunger

The fuel injection pump on diesel engines of cars and light vehicles is generally a distribution type, which has the advantages of small size, light weight, few parts, and simple structure. It uses two sets of plunger systems (or one set of plunger systems) to pressurize, and diesel is sent to each fuel injector separately

Its basic working principle is that there are two sets of opposing plungers installed on the impeller inside the pump. When the impeller is driven to rotate by the engine, the plungers also rotate. Due to the protruding part of the cam ring pressing the plunger, the plunger works like a pump and sends diesel to the oil supply hole in the center of the impeller. At this time, the diesel sent out fills the inlet of the distributor and is then arranged and injected in order of each cylinder

Due to the proportional increase in the operating speed of two plunger systems (or one plunger system) to the number of cylinders, this type of fuel injection pump is limited by the number of cylinders and the maximum speed

That is, the diesel engine generates high-pressure fuel from a distribution pump (the oil pressure of the high-pressure fuel generated by the distribution pump is much lower than that of the high-pressure fuel in the common rail of a common rail diesel engine), which is injected into the cylinder of the diesel engine through the fuel injector. A diesel engine can have only one distribution pump because the engine is directly injected into the cylinder

With the development of diesel engine technology, there is now a new form of single unit fuel injection pump (called single unit pump or pump nozzle), which actually "breaks down" the above two types of fuel injection pumps, and the fuel injection of each cylinder of the engine is completed by its own independent injection unit (single unit pump or pump nozzle)

For a single unit pump, the fuel injection pump is connected to the fuel injection nozzle by a short high-pressure oil pipe, while for the pump nozzle, the fuel injection pump and nozzle are combined as one and directly installed on the cylinder head of the diesel engine, driven by the overhead camshaft. Their greatest advantage is that they can alleviate or eliminate the pressure wave effects formed in the high-pressure fuel pipe during diesel flow and injection. Because this pressure wave will hinder the good matching of the fuel injection system with the load and speed, and will increase with the length of the high-pressure pipe

Therefore, shortening the length of the high-pressure oil pipe (the design idea of the fuel injection pump) or simply not using the high-pressure oil pipe (the design idea of the pump nozzle), reducing the high-pressure volume between the plunger and the fuel injection nozzle, can obtain a fuel supply law that is close to the cam contour line. Especially the pump nozzle, which was already applied to General Motors more than a decade ago, now has precise control of electronic technology to improve its performance. Common diesel engine mechanical fuel injection pumps include A-type pump, B-type pump, P-type pump, VE type pump, etc. The first three types belong to plunger pumps; VE pump system is a distributed rotor pump

4D56 and 4M40 use a distributed pump diesel engine, which means that the fuel supply system of the diesel engine adopts a distributed fuel injection pump for fuel supply

That is, the diesel engine generates high-pressure fuel from a distribution pump (the oil pressure of the high-pressure fuel generated by the distribution pump is much lower than that of the high-pressure fuel in the common rail of a common rail diesel engine), which is injected into the cylinder of the diesel engine through the fuel injector. A diesel engine can have only one distribution pump because the engine is directly injected into the cylinder

A diesel engine that uses a common rail system for fuel injection is called a common rail diesel engine

The so-called common rail system refers to a high-pressure common rail (used to store high-pressure diesel, equipped with pressure sensors, pressure fluctuation regulators, injectors, and other components) and a high-pressure pump (high-pressure generating device). The common rail system generates sufficient high-pressure fuel and keeps the fuel pressure fluctuation in the common rail within a controllable range. The ECU determines the amount of fuel injected into the cylinder based on the common rail fuel pressure and engine operating conditions, and injects an appropriate amount of diesel into the cylinder through the fuel injector (ECU controls the opening and closing of the injector)

For the second-generation electronic fuel injection system, according to the different high-pressure generating devices, the fuel injection system can be divided into distribution pump, inline pump, pump nozzle, and single pump electronic fuel injection system. The unit pump is used to generate the injection pressure of the fuel injector (or injector). For engines that use a single pump electronic fuel injection system, there are as many single pumps as there are cylinders

In summary, the difference between the two can be drawn: the single unit pump is only a high-pressure generating device in the second-generation electronic fuel injection system, and as many cylinders as there are, several single unit pumps are required; Electronic common rail is the third generation electronic fuel injection system, which has superior performance compared to the second generation and is the mainstream of the development of electronic fuel injection systems

PS: The maximum pressure in the common rail can reach 150Mpa. Due to the large volume of the common rail and the presence of pressure fluctuation regulators, the common rail pressure remains relatively constant during engine operation, thus meeting the fuel injection requirements of the engine at any time; The pressure generated by a single unit pump is lower than that of a high-pressure pump, generally around 100Mpa, and the amount of high-pressure fuel generated by a single unit pump is limited